FRP Products

Magic Composites, Inc. specializes in Fiberglass Reinforced Plastic (FRP) production. We specialize in hand lay-up, spray-up, resin transfer molding (RTM), and compression molding using polyester, vinyl ester, and epoxy resins.

Hand Lay-Up and Spray Up

One of the most basic of FRP manufacturing processes, Hand Lay-up involves applying and forming each resin/glass laminate layer manually into an open mold until the desired part thickness is achieved. Because of the close control of material application, it is the method of choice for producing many fiberglass parts.

Resin Transfer Molding (RTM)

In Resin Transfer Molding (RTM), dry fiberglass reinforcement is first loaded into a closed mold. Resin is then injected into the mold to form the finished part. Because the material is completely enclosed within the mold in net or near-net shape, RTM offers superior surface finishes, close control of tolerances and less material waste.

Compression Molding

Matched die molding of a premix paste of chopped glass reinforcement and resin is called Compression Molding. This process is widely used to manufacture parts in situations where large production quantities offset the method's increased cost of tooling.

|

|

|

|

Magic can manufacture tanks and process vessels to meet virtually any storage or process requirement.

MAGIC offers industrial air quality engineered solutions, packaged fan & blower equipment and custom blowers / fans units.

|

FRP Duct is available in a wide variety of corrosion resistant materials, shapes and thickness

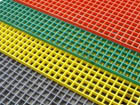

MAGIC provides a wide range of Fiberglass Reinforced Plastic (FRP) Grating including Molded FRP Grating, Standard Resin Systems and Pultruded FRP Grating.

|

Piping systems can be manufactured by contact moulding (hand lay-up) or hand lay-up in combination with filament winding.

|